ABOUT THIS PRODUCT

The Model 2100 Digital Level Sensor (DLS) utilizes reed-switch technology to accurately measure total fluid level, water-interface level, and fluid temperature. It accommodates up to eight temperature sensors along its length to monitor various temperature zones, ensuring precision without cumulative errors. With a single control unit, it can monitor up to 32 tanks containing fluids such as crude oil, diesel, kerosene, and more. The user is able to measure one or two levels with an additional third level with a high-level alarm and shut-in option. The high-level alarm shut-in requires no power and, unlike competitors’ sensors, is unaffected by power outages. Available in three measurement increments and lengths between 2 and 48 feet.

PRODUCT DETAILS

- Digital Level Sensor (DLS)

- Temperature Reading

- Single- or Dual-Float Options

FLEX

- Lengths up to 48′.

- Patent-pending flexible, rugged, chemically and abrasion-resistant digital level sensor for reliable tank monitoring

- A bend radius of 36″ makes the RU Flex Sensor a one-man installation job.

- Electrolab RU Flex Level Sensors are able to measure fluid levels and temperature measurements through a single tank port.

STAINLESS STEEL

- Lengths up to 35′.

- All stainless steel parts treated with e9 Treatments Pro Performance metal surface treatment to repel paraffin and other contaminants.

FIBERGLASS

- Lengths up to 33′.

- For corrosive/caustic environments.

DOCUMENTS

RELATED PRODUCTS

ELECTROLAB REDILEVEL 2100 DIGITAL LEVEL SENSOR

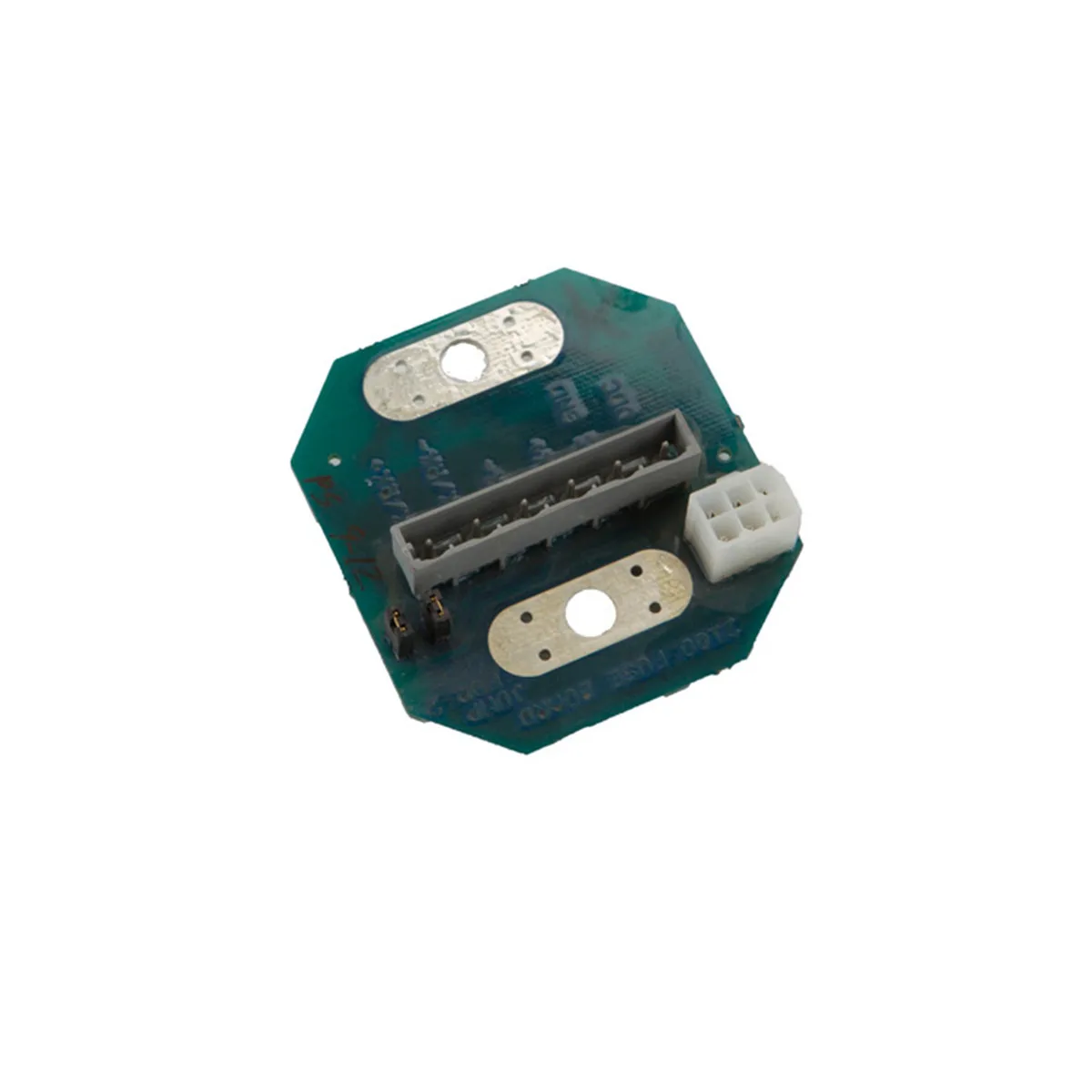

ELECTROLAB DLS FUSE BOARD REPLACEMENT

ELECTROLAB FLOAT REPLACEMENT

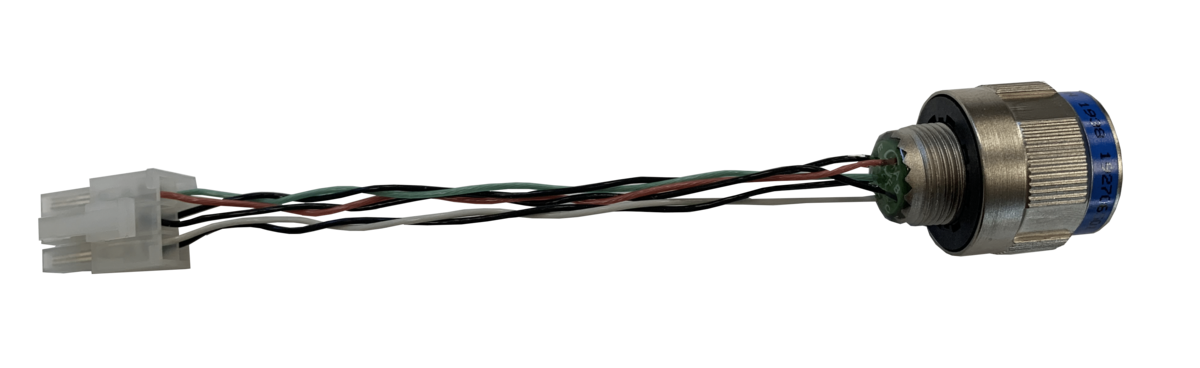

ELECTROLAB PIGTAIL REPLACEMENT PART